Every time you switch on a light, plug in your phone, or operate a heavy machine, an invisible safety system works silently to protect you — electrical earthing. It is one of the most critical yet often ignored aspects of electrical safety. Whether you live in an apartment, manage an office, or run a factory, a proper earthing system ensures that you, your appliances, and your building stay safe from electrical hazards.

What is Electrical Earthing?

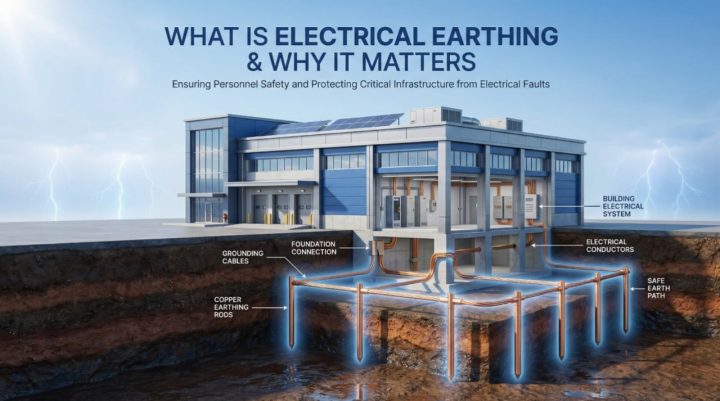

Electrical earthing (or grounding) is the process of connecting electrical systems and metallic parts of equipment directly to the earth. The goal is simple — to provide a safe path for excess or fault current to travel into the ground instead of passing through people or devices.

When a fault occurs (like a short circuit or insulation failure), the earthing system diverts dangerous currents safely into the soil. This prevents electric shocks, burns, fires, and equipment damage.

In India, electrical safety standards such as IS 3043 emphasize the importance of proper earthing in all electrical installations — from homes and hospitals to factories and solar plants.

Why Electrical Earthing Is Important

Without earthing, even a small electrical fault can become life-threatening. Here’s why earthing is essential for every type of setup:

1. Prevents Electric Shocks

A properly earthed connection ensures that stray currents do not flow through the human body. When a person touches a metal appliance, the current immediately takes the low-resistance path to earth instead of through the person.

2. Protects Electrical Equipment

Earthing shields appliances and machines from sudden voltage surges, lightning strikes, or insulation failures. This reduces wear, improves performance, and increases the lifespan of your equipment.

3. Maintains Voltage Stability

Earthing stabilizes the voltage levels across the entire system by ensuring all metallic components remain at the same potential. It keeps the current balanced and prevents overloading.

4. Prevents Fire Hazards

Uncontrolled electrical leakage can generate heat and cause fires. Earthing instantly discharges this fault current to the ground, minimizing such risks.

5. Protects Property & Lives

In commercial and industrial settings, earthing systems protect costly machinery, servers, and control panels. For homes, they ensure everyday safety for your family.

How Does Electrical Earthing Work?

When a fault occurs in an electrical system, a large amount of current flows through the fault path. The earthing conductor connects this path to an earth electrode (buried in the ground).

This electrode provides a direct, low-resistance route for the current to disperse harmlessly into the soil. In simpler words — earthing acts like a safety valve that releases excess electricity safely into the ground.

Main Components of an Earthing System:

- Earth Electrode: Metal rod or plate buried in the earth to dissipate current.

- Earth Conductor: Copper or GI wire that connects the system to the electrode.

- Earth Pit: The area where the electrode is installed and maintained.

- Enhancement Material: Chemical or conductive material to reduce resistance.

A properly designed earthing system ensures that even during heavy faults or lightning, dangerous voltages never reach the user or electrical network.

Types of Earthing Systems in India

Different industries and building types use various earthing methods depending on load, soil condition, and maintenance needs.

1. Pipe Earthing

One of the oldest and most economical methods, where a galvanized iron (GI) pipe is inserted vertically into the ground. It’s ideal for small homes and low-load buildings.

2. Plate Earthing

In this system, a copper or GI plate is buried in the soil at a depth of around 3 m. It’s suitable for industrial applications where larger fault currents may occur.

3. Chemical Earthing

This modern method uses chemical compounds and conductive salts to lower soil resistance. RIG Earthing’s chemical earthing systems are maintenance-free, corrosion-resistant, and offer consistent performance in all weather conditions.

4. Maintenance-Free Earthing

Used in modern infrastructures like telecom towers, solar plants, and data centers. It uses copper-bonded rods with backfill compounds to maintain long-term low resistance without frequent watering.

5. Earthing with Lightning Protection

In this setup, lightning arresters are connected to the earthing system to protect buildings from lightning strikes by channeling the surge safely into the earth.

Earthing for Homes vs. Businesses

Earthing for Homes

Residential earthing systems focus on personal safety, preventing shock hazards and protecting daily-use appliances like refrigerators, washing machines, and TVs. A single earthing pit is often sufficient, but the installation must follow proper IS standards.

Earthing for Businesses & Industries

Commercial and industrial spaces require stronger earthing networks due to higher loads and complex machinery. These setups often involve multiple electrodes, lightning arresters, and equipotential bonding systems to ensure safety and uninterrupted power.

RIG Earthing offers specialized earthing systems for industries like:

- Solar power plants

- Telecom towers

- Manufacturing units

- Hospitals & data centers

- Construction sites

Consequences of Poor or No Earthing

Ignoring earthing is like removing the seatbelt from your electrical system. The results can be disastrous:

- Severe Electric Shocks: Any leakage current may flow through human contact.

- Equipment Damage: Sensitive electronics like inverters, servers, and motors burn out.

- Fire Accidents: Excess current can cause overheating of wires and connections.

- System Failure: Unstable voltage leads to frequent tripping and outages.

- Non-Compliance: Buildings without proper earthing violate safety regulations and risk insurance rejections.

Real-world incidents show that many electrical fires are caused by improper earthing or neglected maintenance.

Modern Earthing Solutions by RIG Earthing

At RIG Earthing, safety meets innovation. The company provides a complete range of chemical and maintenance-free earthing solutions designed for durability, performance, and compliance.

Our Product Range Includes:

- Chemical Earthing Electrodes – Using advanced conductive compounds for low resistance.

- Copper Bonded Rods – High conductivity and corrosion resistance.

- Ground Enhancement Material (GEM) – Ensures long-lasting, stable earth resistance.

- ESE Lightning Arresters – Protects buildings from direct lightning strikes.

- Earthing Accessories – Earth pits, clamps, and inspection chambers.

Why Choose RIG Earthing

When it comes to protecting your property, people, and electrical systems, choosing the right earthing partner makes all the difference. RIG Earthing stands as a trusted name in the industry, offering high-performance and safety-compliant earthing solutions that ensure reliability for years to come.

ISO-Certified and IS-Compliant Products:

RIG Earthing’s products are manufactured under strict quality control, adhering to ISO standards and IS 3043 earthing guidelines. This ensures that every component — from electrodes to lightning arresters — meets national and international safety requirements, delivering consistent performance and long-term protection.

Proven Installations Across South India:

With successful projects executed across Tamil Nadu, Kerala, Karnataka, and Andhra Pradesh, RIG Earthing has earned the trust of industries, builders, and government bodies alike. From residential complexes to large-scale industrial plants, our solutions are known for durability and efficiency even in challenging soil and weather conditions.

Expert Team for On-Site Assessment and Design:

Every project begins with a thorough site study conducted by our skilled engineers. They assess soil resistivity, system requirements, and load conditions to design an optimized earthing plan tailored for your site. This technical precision ensures maximum safety and performance.

Long-Term, Maintenance-Free Performance:

Our chemical earthing and maintenance-free systems use advanced materials that resist corrosion, reduce earth resistance, and eliminate the need for frequent watering or replacement — offering stability for years with minimal upkeep.

Fast Installation and After-Sales Support:

RIG Earthing ensures quick, hassle-free installation with professional supervision and comprehensive after-sales service. Our team remains available for resistance testing, inspection, and annual maintenance checks.

With decades of expertise, RIG Earthing continues to help households, industries, and builders achieve safe, efficient, and globally compliant earthing systems they can trust.

Maintenance Tips for a Reliable Earthing System

Even the best earthing system needs occasional checks to stay effective. Here are a few maintenance practices recommended by RIG Earthing experts:

- Measure Earth Resistance Regularly: Should remain below 1 ohm for sensitive systems.

- Keep the Earth Pit Moist: Refill with water or use backfill compounds during dry seasons.

- Inspect Connections Annually: Look for loose joints or corroded metal parts.

- Avoid Using Common Water Lines for Earthing: Always have a dedicated electrode.

- Schedule Professional Testing: Get certified engineers to test performance every 12 months.

By following these steps, you can ensure consistent performance, electrical safety, and compliance for years.

Frequently Asked Questions

1. What is the main purpose of electrical earthing?

It safely transfers excess or fault current from electrical systems to the ground, protecting people and equipment from shocks or damage.

2. What are the most common types of earthing?

Pipe earthing, plate earthing, and chemical earthing are widely used in India, depending on the application.

3. How often should an earthing system be checked?

At least once a year, or more frequently in high-load industrial setups.

4. What happens if there is no earthing at home?

Without earthing, fault current may flow through people or equipment, causing shocks, fires, or complete system failure.

5. Why choose chemical earthing?

Because it’s maintenance-free, corrosion-resistant, and maintains low earth resistance in all soil conditions.

Conclusion

Electrical earthing is not just a technical requirement — it’s a life-saving system that protects homes, businesses, and people from electrical hazards. It ensures your property remains safe, your devices perform better, and your family or staff stay protected from electric shocks.

At RIG Earthing, we believe safety begins with a solid foundation. Our chemical and maintenance-free earthing systems are engineered to deliver consistent protection for residential, commercial, and industrial applications.

“Protect your building from unseen electrical risks — choose RIG Earthing, your trusted partner for safe and reliable earthing solutions.”

Contact us today to know more or request a site assessment for your next project.